The post Retrofitting MEP Systems: What Building Owners Should Know appeared first on Melissa Test Site.

]]>But retrofitting isn’t just about replacing old equipment. For building owners, it’s a strategic decision that involves weighing energy savings, occupant comfort, regulatory compliance, and environmental impact—especially when it comes to operational and embodied carbon.

This blog explores what building owners should know when planning an MEP retrofit and how to make decisions that align with long-term building performance, financial, and sustainability goals.

What Does Retrofitting MEP Systems Involve?

Retrofitting MEP systems involves upgrading a building’s mechanical, electrical, and plumbing infrastructure to improve efficiency, reliability, and code compliance—without full replacement. These targeted improvements often include high-efficiency equipment upgrades, smart lighting controls, low-flow plumbing fixtures, and updated electrical systems. The goal is to boost performance while minimizing cost and disruption to the existing structure.

What Building Owners Should Evaluate Before Retrofitting

A successful MEP retrofit begins with a clear understanding of your building’s current systems, future needs, and project goals. Taking the time to evaluate key factors upfront helps prioritize improvements, avoid costly missteps, and maximize the long-term value of your investment.

Here are key considerations building owners should keep in mind:

System Age and Condition

One of the first signs your building may be due for an MEP retrofit is the declining performance of core systems. Even well-maintained equipment loses efficiency over time. If systems are underperforming, difficult to service, or breaking down more often, retrofitting may be the most cost-effective way to restore reliability and prevent future disruptions.

Energy Consumption and Operating Costs

If your utility bills continue to climb without a corresponding increase in usage, your building may be losing efficiency. Retrofitting can help by replacing energy-intensive systems and adding smart controls to better manage demand.

An energy audit is a valuable first step for identifying performance gaps and areas where retrofitting can deliver a measurable return.

Operational and Embodied Carbon

An effective retrofit plan considers the building’s total carbon footprint, including both operational and embodied carbon. Operational carbon comes from the daily energy use of heating, cooling, lighting, and water systems. Upgrading outdated MEP systems is one of the most effective ways to reduce these emissions by improving energy efficiency.

Embodied carbon, refers to the emissions generated over the lifecycle of building materials and systems—from manufacturing to installation and maintenance. Because MEP systems are component-heavy and replaced periodically, they contribute significantly to the embodied carbon footprint of a building over time.

When planning a retrofit, building owners should aim to maximize operational carbon reductions while minimizing embodied carbon impacts. Prioritizing energy-efficient upgrades, extending system life where feasible, and selecting lower-carbon equipment upgrades supports both immediate and long-term sustainability goals.

Code Compliance and Regulatory Requirements

Building codes for ventilation, lighting, energy use, and life safety are updated regularly. Older MEP systems that once met standards may now fall short. Retrofitting provides an opportunity to address compliance issues proactively, avoiding costly penalties or disruptions to building operations.

Before planning a retrofit, owners should review current codes, upcoming regulations, and permitting requirements to ensure upgrades meet all necessary standards and protect the building’s long-term value.

Occupant Comfort and Usage Changes

Comfort issues like inconsistent temperatures, poor air quality, or unreliable water pressure are common triggers for MEP upgrades. If you’re also changing how the space is used—like increasing tenant density or repurposing areas—your systems may need to be reconfigured or upgraded to meet new demands.

Project Budget and ROI

Retrofitting MEP systems requires substantial upfront investment, but the long-term returns often outweigh the costs. Benefits can include lower utility bills, reduced maintenance expenses, higher tenant satisfaction, and improved asset value. Incentives, tax credits, or green financing options may also help offset initial costs.

Working with experienced MEP engineers allows you to model projected savings, evaluate payback periods, and phase upgrades strategically to align with your financial goals.

When to Engage MEP Engineers in Retrofit Projects

MEP engineers should be brought in at the very beginning of the retrofit planning process—before decisions are made about scope, equipment, or budget. Retrofitting existing buildings often presents coordination, access, or infrastructure challenges that aren’t always visible at the outset. Engaging your engineering team early ensures that system conditions are properly assessed, priorities are aligned with your goals, and critical elements like energy savings, code compliance, and carbon impact are factored into the design from the start.

Here’s how MEP engineers support a successful retrofit:

System Assessment and Analysis

Engineers can evaluate your current systems, identify inefficiencies, and provide recommendations tailored to your building’s needs and constraints.

Energy Modeling and Carbon Planning

Through energy modeling and performance simulations, engineers can predict how different retrofit options will affect operational energy use, costs, and emissions—helping you prioritize the best solutions.

Code Compliance and Permit Support

MEP engineers ensure your retrofit plan aligns with all applicable building codes and standards, avoiding costly revisions or delays during the permitting process and during construction.

Design, Coordination, and Commissioning

From system design and construction coordination to final testing and commissioning, engineers oversee the entire process to ensure systems are integrated properly and operating as intended.

Waiting until after decisions are made can lead to missed savings, rework, or systems that don’t perform as expected. Bringing MEP engineers in early sets the entire project up for long-term success.

Final Thoughts

Retrofitting MEP systems is more than an equipment upgrade—it’s a strategic investment in efficiency, sustainability, and long-term building performance. By evaluating system conditions, carbon impacts, and operational costs early, building owners can make decisions that protect both building value and environmental goals.

With decades of experience in retrofitting MEP systems for commercial buildings across the nation, Schnackel Engineers helps building owners identify efficient, cost-effective solutions. Using our proprietary AI for MEP® software, we deliver optimized designs that minimize disruption and maximize long-term value. Contact us today to explore retrofit options for your building.

The post Retrofitting MEP Systems: What Building Owners Should Know appeared first on Melissa Test Site.

]]>The post How AI-Powered MEP Firms Give Architects a Competitive Edge appeared first on Melissa Test Site.

]]>1. Faster Project Completion, Winning More Work

In today’s fast-paced industry, speed matters. Firms equipped with AI-powered MEP capabilities significantly reduce the time traditionally spent on designing complex building systems. Advanced AI systems automate time-consuming processes, rapidly producing accurate and optimized MEP layouts. Architects benefit directly by receiving faster turnaround times, enabling them to complete projects ahead of competitors. This speed is an undeniable advantage, helping architects secure more projects and strengthen their market position.

2. Fewer Errors, Happier Clients, and Less Overhead during Construction Administration

AI systems efficiently handle repetitive and intricate tasks like sizing and routing wires, pipes, and ducts. By automating these processes, they substantially reduce errors that typically surface during construction. This results in fewer RFIs, reduced administrative overhead, and smoother construction phases. Architects experience fewer headaches, happier clients, and greater satisfaction, ultimately translating into increased repeat business and positive referrals.

3. Greater Design Freedom, Enabling Unique and Innovative Concepts

Architects are inherently creative, continuously pushing boundaries to design unique and inspiring spaces. AI-powered MEP solutions facilitate greater architectural freedom by optimizing infrastructure to occupy minimal space and reduce conflicts. Engineers, relieved of mundane tasks, can focus on complex problem-solving and enhancing the overall building experience. Architects thus gain the freedom to propose more innovative designs without being constrained by traditional MEP process limitations.

4. Lower Construction Costs, Better Buildings

Cost-efficiency is a critical factor for both architects and their clients. AI-driven MEP solutions optimize building system layouts, significantly lowering installation costs. Savings on infrastructure are redirected to enhancing architectural elements such as premium finishes, advanced fixtures, and additional amenities. Moreover, fewer errors and reduced changes during construction further ensure projects remain within budget, making architects highly appealing to value-driven clients.

5. Fewer Project Delays, Enhancing Reputation and Client Trust

Project delays can damage both reputation and profitability—and coordination challenges are often a major cause. AI-powered MEP designs reduce these delays by resolving clashes and inconsistencies early in the design process. By minimizing coordination issues across disciplines and streamlining communication, architects can keep projects on track. Consistently delivering on or ahead of schedule strengthens an architect’s reputation for reliability, builds client trust, and opens the door to more repeat work and long-term growth.

Schnackel Engineers and AI for MEP®: Delivering Competitive Advantages

At Schnackel Engineers, we’ve developed our proprietary AI-powered design software, AI for MEP®, to offer architects the competitive advantages they need. Our tool rapidly evaluates thousands of possible solutions, delivering optimized, accurate, and efficient MEP system designs faster and with fewer errors than is possible with traditional methods. The advantages include:

- Speed and Accuracy: Automating complex processes ensures accurate results, significantly reducing project timelines. Fewer errors means less time during Construction Administration resolving them.

- Enhanced Creativity: Optimized infrastructure layouts mean architects can explore more ambitious design concepts. In addition, since our engineers and designers are not burdened with routine calculations and drafting, they can spend more time focusing on what matters most – the user experience.

- Budget Optimization: AI-driven cost reductions translate into better resource allocation, improved finishes, and enhanced overall project value. The AI generated designs are less expensive to build and to operate over the life of the building.

- Sustainability Leadership: AI-driven efficiency helps projects effortlessly meet or exceed sustainability and energy goals. The reduction in labor and materials translates directly into both embodied carbon and operational carbon reduction, resulting in a more eco-friendly design.

Bottom Line

In a highly competitive architectural landscape, partnering with an AI-powered MEP firm like Schnackel Engineers offers a significant advantage. By leveraging cutting-edge AI technology, architects can achieve faster timelines, lower costs, enhanced creativity, and unmatched sustainability. Ultimately, choosing AI-powered solutions means better project outcomes, greater client satisfaction, and increased market competitiveness.

Are you ready to elevate your firm’s competitive advantage with AI-powered MEP design?

Contact Schnackel Engineers today to see how our cutting-edge solutions can transform your next project.

The post How AI-Powered MEP Firms Give Architects a Competitive Edge appeared first on Melissa Test Site.

]]>The post Key Challenges in Expanding Hawaii’s EV Charging Infrastructure appeared first on Melissa Test Site.

]]>While progress is being made, developing a reliable and accessible EV charging network in Hawaii comes with unique challenges. Factors such as increased electrical demand, limited space, high installation costs, and infrastructure integration can add complexity to both new and existing projects. Understanding these factors—along with the specific requirements of EV charging systems—is essential for making informed decisions and contributing to Hawaii’s clean energy future.

1. Building Electrical Infrastructure

Many stakeholders are not fully aware of the scale of electrical upgrades involved in EV charging installations. While adding chargers may appear straightforward, the process is often far more complex—particularly at larger properties where demand can increase significantly.

EV Charging Systems without Load Management

The 2020 National Electrical Code (NEC) requires that electric vehicle charging loads not equipped with a load management system must be considered continuous loads, meaning that all circuits, overcurrent protection, and distribution equipment associated with EV charger(s) are required to be sized at 125% of the EV charging load being served.

Examples:

- A 40-amp, 208-volt, single-phase Level 2 charger, when calculated at 125 percent, is required to be considered a 50 amp load when sizing circuits and equipment.

- In a smaller commercial building, installing 12 of these chargers, evenly balanced across the phases, would require 346 amps at 208Y/120V, 3-phase or 150 amps at 480Y/277V, 3-phase to be considered the total load of the EV chargers—a significant increase for a small building.

- In a condominium building with 300 units, installing one of these chargers for each unit would require 8,660 amps at 208Y/120V, 3-phase or 3,753 amps at 480Y/277V, 3-phase. These values would require two 208Y/120V, 3-phase services or one 480Y/277V, 3-phase service dedicated to the EV chargers.

- If each of the 300 condominium units used a Tesla wall connector rated at 48 amps, requiring the charger to be considered a 60 amp load, the total demand would rise to 10,392 amps at 208Y/120V, 3-phase—highlighting the scale of infrastructure needed for full-building EV readiness.

EV Charging Systems with Load Management

In an effort to minimize the impact EV chargers can have on a power distribution system, the 2020 NEC contains a special provision that allows an automatic load management system to be implemented. When an automatic load management system is implemented, the required calculated EV charging load is allowed to be the maximum load permitted by the automatic load management system.

An automatic load management system for a system of EV chargers is a software-driven system that can limit the total power drawn by the EV charging system, while simultaneously optimizing the charging for each charger.

If the small commercial building example above only had 200 amps available that could be allocated to EV chargers, the load management system would limit the total power drawn by the 12 chargers to some pre-programmed value of less than 200 amps, ensuring the building infrastructure will not be overloaded. The load management system will also prioritize the chargers that have vehicles with a low charge state by maximizing the power given to those chargers, while reducing the power serving the chargers that are serving vehicles with a higher charge state.

Automatic load management systems do have their caveats. An EV charger’s output power is directly related to the charger’s input power, meaning that the output power is reduced if the input power is reduced. Electric vehicle charging times are directly related to the output power of the connected charger. Therefore, when an automatic load management system reduces the power to an EV charger, the charging time associated with that EV charger will increase, which could lead to user complaints based on their experience at other charging facilities. In addition, severely limiting the managed systems output to match the existing electrical service conditions often leads to a reduced total number of chargers that can be reasonably supported on an existing service.

2. Space Constraints for Electrical Upgrades

Space limitations, particularly in dense urban areas like Honolulu, create significant challenges for expanding EV charging infrastructure. While installing commercial charging hubs, like at gas stations, is feasible, space constraints become more pronounced when considering installations within buildings.

In new developments, architects and engineers must juggle competing priorities for space. Allocating room for electrical distribution and charging infrastructure near parking areas may result in losing valuable parking stalls. This tug-of-war over space often forces EV infrastructure to be deprioritized during value engineering efforts.

Retrofitting existing buildings is even more complex. Electrical rooms in older facilities are often too small to accommodate upgraded switchgear required for EV charging. If the building’s utility service needs to be upgraded, the new service must meet stringent requirements, such as encasing utility feeds in concrete—a near-impossible task in a fully built structure.

3. High Cost of Upgrading Electrical Services

The cost of upgrading utility services and installing EV infrastructure can be excessively high, especially for large properties. Retrofitting a condominium with sufficient capacity to support multiple EV chargers requires costly upgrades to services, electrical panels, transformers, and distribution systems.

With respect to new construction, designing to accommodate widespread EV adoption triggers enormous electrical service requirements, which are often cut during value engineering due to their high construction cost.

For older buildings, utility upgrades are often out of reach. If the electrical service was sized decades ago based on historical loads, there’s often little room to add charging stations without triggering a complete overhaul—an investment that many building owners are hesitant to make.

4. Limited Grid Capacity and High Demand during Peak Hours

As EV adoption grows, so does the demand for electricity—especially in the evening when most people charge their vehicles. Unfortunately, this is also when energy usage is already at its highest and solar production drops off, creating a mismatch between supply and demand.

Programs like demand-side management, demand response, and time-of-use rates weren’t created specifically for EVs, but their existence highlights a larger issue: There are already production challenges during peak hours. Utilities are actively working to manage demand, but the growing number of EVs will only increase pressure on the grid when it’s least equipped to handle it.

Without careful planning and infrastructure upgrades, the system may struggle to support the added demand from widespread EV charging during these critical hours.

5. Expectations and the Need for Clear Guidance

Installing EV chargers can seem straightforward at first glance, but large-scale implementation—especially in multi-unit residential buildings—often involves significant electrical and infrastructure considerations. Without a clear understanding of what’s involved, expectations around cost, feasibility, and timelines can differ from the actual requirements.

At the policy level, efforts to support EV adoption, such as rules that prevent condominium boards from denying charger requests, are a positive step forward. However, these policies may not always reflect the full scope of upgrades needed to support widespread charging in existing buildings. Clearer guidance can help all stakeholders—including property owners, developers, and policymakers—navigate the technical and financial realities of expanding EV infrastructure effectively and efficiently.

Conclusion: What Property Owners and Developers Need to Know

Understanding the impact of EV charging on electrical infrastructure is key to making well-informed decisions. With growing demand and evolving regulations, it’s important to consider the electrical load, space requirements, and cost implications early in the planning process.

EV charging projects can be challenging—but they’re far from impossible. With the right planning and support, these efforts can be successfully integrated into both new developments and existing buildings. Hiring experienced consultants early in the process can help you navigate technical and logistical hurdles, avoid costly surprises, and move forward with confidence.

Schnackel Engineers has decades of experience guiding clients through complex infrastructure projects. Whether you’re planning a new development or exploring options for an existing property, our team can help you implement EV solutions that are practical, scalable, and aligned with your long-term goals.

Ready to get started? Contact Schnackel Engineers today to discuss your EV charging project. Let us help you turn challenges into opportunities for long-term success.

The post Key Challenges in Expanding Hawaii’s EV Charging Infrastructure appeared first on Melissa Test Site.

]]>The post Siphonic vs. Gravity Storm Drainage Systems: Weighing the Pros and Cons appeared first on Melissa Test Site.

]]>By the end of this blog, you’ll have a better understanding of which drainage system might be the best fit for your next project, whether you’re dealing with large or smaller commercial buildings.

What is a Siphonic Drainage System?

A siphonic drainage system relies on the principles of siphon action to efficiently remove rainwater from roofs. These systems use negative pressure to create a vacuum effect in the piping network, allowing rainwater to be carried away through smaller diameter pipes. The siphon effect accelerates the water flow, making it more efficient compared to gravity systems. This results in reduced piping requirements and faster drainage, especially beneficial for large or flat roofs.

What is a Gravity Drainage System?

A gravity drainage system, on the other hand, uses gravity to move rainwater from a roof to a drainage system. Water flows downhill through large-diameter pipes, relying on slope to transport the water. Gravity systems are the traditional method used in most buildings, and they require a well-maintained slope to ensure that water flows efficiently towards the drains.

What’s the difference between Siphonic and Gravity Drainage Systems?

Functionality and Operation

Siphonic drainage systems rely on the vacuum effect generated by negative pressure within the pipes to efficiently move water off the roof. This siphonic action accelerates the flow of water, allowing the system to handle larger volumes with smaller pipes compared to gravity systems. The result is a more efficient and compact drainage solution that is ideal for large, flat roofs or areas with high rainfall. In contrast, gravity drainage systems function by using gravity to move water downhill through large pipes and drains. While gravity systems are simpler and more traditional, they require a specific slope to function effectively. Without the right pitch, water flow may slow down, and drainage efficiency may be compromised.

Pipe Size and Piping Requirements

One of the significant advantages of siphonic systems is their use of smaller pipes, which reduces the amount of piping needed overall. This not only lowers material costs but also cuts down on installation time. Additionally, the smaller pipes offer more flexibility in terms of placement within the building, making it easier to design and install a drainage system that fits into tighter spaces. Conversely, gravity systems require larger-diameter pipes to move water effectively, which can take up more space and increase both material costs and installation time. This can be especially challenging in larger buildings where roof space is limited, or when dealing with complex layouts that require extensive piping networks.

Pros and Cons of Siphonic Drainage Systems

Pros:

- Increased Efficiency: Siphonic drainage systems are better at handling high volumes of rainwater quickly. The siphonic action accelerates water movement, making them ideal for large roofs or areas with heavy rainfall.

- Reduced Piping Needs: With smaller pipes required, the overall material and labor costs are reduced. Fewer drains and piping make the system more compact and efficient.

- Design Flexibility: The system’s smaller pipes offer greater flexibility in roof design. It allows for more space utilization and eliminates the need for slopes, making it ideal for complex roof structures.

- Fewer Maintenance Requirements: Siphonic systems are less susceptible to blockages due to the siphonic energy in the system.

Cons:

- Complex Design and Installation: Siphonic drainage systems are more complicated to design and install due to the specialized piping and technology involved.

- Higher Initial Costs: Though they save on material costs due to smaller pipes, the technology and specialized installation can make siphonic systems more expensive upfront.

Pros and Cons of Gravity Drainage Systems

Pros:

- Simplicity and Reliability: Gravity drainage systems are the traditional choice and are simpler to design, install, and maintain. Their operation is easy to understand, making them ideal for less complex roof designs.

- Lower Upfront Costs: Gravity systems are generally less expensive to install due to the simplicity of their design and fewer specialized components.

Cons:

- Space and Design Limitations: Large pipes and the need for a slope can limit roof design flexibility. The system can take up more space, especially in buildings with complex layouts.

- Slower Water Drainage: Gravity systems can struggle to remove large volumes of water quickly, particularly during intense rainfall, leading to pooling and possible water damage on the roof.

- Drainage Constraints: Gravity drainage systems are less effective in regions with heavy rainfall or in buildings with flat roofs where water flow is less efficient.

- More Maintenance Requirements: Gravity systems typically experience more blockages and require more maintenance over time compared to siphonic systems.

Final Thoughts

Both siphonic and gravity drainage systems have distinct advantages, and understanding their differences is key to making an informed decision for your project. Siphonic systems are efficient, flexible, and ideal for large, complex roofs, especially in areas with heavy rainfall. However, gravity systems are simpler, more cost-effective, and reliable for smaller or traditional buildings with less demanding drainage needs.

By evaluating factors such as budget, roof design, climate, and long-term maintenance, you can select the best drainage system for your building project, ensuring optimal performance and longevity.

Ready to optimize your building’s storm drainage system?

Contact us today to discuss how our engineering expertise can help you design the most efficient and cost-effective drainage solution tailored to your needs. Let’s make your project a success with the right drainage system!

The post Siphonic vs. Gravity Storm Drainage Systems: Weighing the Pros and Cons appeared first on Melissa Test Site.

]]>The post The Advantages of AI-Powered MEP Design over Traditional Methods appeared first on Melissa Test Site.

]]>What is AI-Powered MEP Design?

AI-powered MEP design refers to the use of artificial intelligence and advanced computer algorithms to automate and optimize the design of mechanical, electrical, and plumbing systems. AI design tools help engineers generate designs that are more efficient and cost-effective than those produced through traditional, manual methods. In addition, AI-powered MEP designs are incredibly fast, compressing days’ worth of engineering work into minutes, with greater accuracy and fewer errors.

This innovation allows engineers to explore multiple design solutions quickly, minimizing errors and maximizing overall system performance. With this approach, teams can achieve better results faster while meeting the growing demand for sustainability and energy-efficient designs.

Advantages of AI-Powered MEP Design

Increased Design Efficiency

One of the primary benefits of AI-powered MEP design is its ability to speed up the design process. Traditional MEP design methods involve a significant amount of manual work, from drawing or modeling system layouts to calculating and sizing pipes, wires, and ducts. With tools like our AI for MEP® software, these repetitive tasks are fully automated, freeing up engineers to focus on more complex challenges and the parts of the project that really matter to the users – how the spaces actually function. The result is faster project delivery with better quality designs.

These AI tools can quickly analyze multiple design scenarios, providing solutions in a fraction of the time it would take using conventional methods. This speed improves overall project timelines and helps reduce delays, making AI a game-changer for time-sensitive projects.

Enhanced Accuracy

In any MEP design, accuracy is critical. Even small errors in calculations can lead to costly mistakes in the field. AI tools optimize designs with a high degree of precision, reducing the likelihood of human error and ensuring the final design is as accurate as possible. This level of accuracy also minimizes the risk of design conflicts between disciplines, which often occur in traditional methods and can lead to expensive rework during construction.

With AI for MEP’s® ability to simulate different scenarios, engineers can be confident that the design meets all necessary performance standards before construction begins.

Cost Optimization

AI-powered design tools also lead to very significant construction cost savings. By optimizing designs for the minimum material and labor usage, AI for MEP® reduces the initial cost of construction and ensures that construction resources are maximized on every project. Traditional design methods are simply incapable of providing the construction cost optimization of these systems, resulting in inefficiencies and wasted resources, both in terms of materials and economic costs.

In contrast, AI’s ability to explore numerous design alternatives quickly allows engineers to achieve the most cost-effective solution, reducing both initial costs and the risk of costly revisions down the line.

Energy Efficiency and Sustainability

As energy efficiency has become a top priority in building design, AI-powered MEP design helps engineers achieve higher levels of efficiency and sustainability. AI tools study thousands of design alternatives, allowing for the optimization of all systems and infrastructure to reduce energy consumption and improve overall building performance. This capability is especially valuable in meeting modern green building standards like LEED certification.

Traditional design methods, lack the ability to perform such extensive and comprehensive simulations. AI for MEP® provides a clear advantage by ensuring both energy and cost efficient solutions are integrated from the outset.

Limitations of Traditional MEP Design Methods

Traditional MEP design methods, in contrast, present an entirely different set of challenges:

- Time-Consuming: Manual design processes are slow, extending project timelines and delaying project completion.

- Increased Risk of Errors: Traditional methods rely heavily on manual calculations, manual routing and manual sizing increasing the likelihood of human errors that could require costly fixes down the line.

- No Optimization: Unlike AI, traditional methods lack the ability to simulate multiple design alternatives, which results in less efficient solutions. This lack of optimization results in higher construction costs and higher energy costs over the life of the building.

- Higher Costs: With more manual intervention and the potential for errors, traditional methods often lead to higher labor costs, material waste, and unexpected expenses.

While these methods have served the industry well for many years, they are being outpaced by the capabilities of AI-powered tools that offer faster, more accurate, and more cost-effective solutions.

Conclusion

AI-powered MEP design is revolutionizing the construction industry, offering remarkable advantages over traditional methods. From improving efficiency and accuracy to reducing costs and enhancing sustainability, AI is transforming how MEP systems are designed. As the construction landscape becomes increasingly complex and expensive, embracing AI is no longer just an option—it’s a game-changer.

At Schnackel Engineers, we are already leading the charge with AI for MEP®, our proprietary software that is redefining how MEP systems are designed and optimized. With AI for MEP®, we are streamlining the design process, automating time-consuming tasks, and delivering cost-effective, energy-efficient solutions faster than ever before.

Ready to be part of the future of engineering?

Our innovative AI-powered software is here to help you navigate the complexities of modern building design. Contact us today to see how AI for MEP® can help elevate your projects, improve collaboration, and deliver optimal results with unmatched speed and precision.

We’re not just keeping up with the future of engineering—we’re redefining it. Let’s build better, faster, and more efficiently with AI for MEP®.

The post The Advantages of AI-Powered MEP Design over Traditional Methods appeared first on Melissa Test Site.

]]>The post Heat Recovery vs. Heat Pump VRF Systems: What’s the Difference? appeared first on Melissa Test Site.

]]>What is Variable Refrigerant Flow (VRF)?

Variable Refrigerant Flow (VRF) technology is an air conditioning system that first gained popularity in Japan during the 1980s and has since become more common in the U.S. market. But what exactly is VRF, and how does it work? In simple terms, VRF efficiently distributes cooling and heating from a single outdoor unit to multiple indoor zones, in a very energy efficient manner. It is a more sophisticated variation of the air conditioning system you probably have in your home or apartment today.

One of the main benefits of VRF systems is their ability to provide zoning capabilities, allowing precise temperature control in different areas of a building. This makes VRF ideal for both small and large spaces, providing comfort exactly where it’s needed. Additionally, VRF systems are known for their quiet operation and space-saving design, which is especially valuable in modern, compact buildings.

Now that you have a general idea of what VRF is and its key benefits, let’s dive into two popular types of VRF systems—Heat Recovery VRF and Heat Pump VRF—and compare their key differences to guide you in choosing the right option for your building.

Heat Recovery VRF Systems

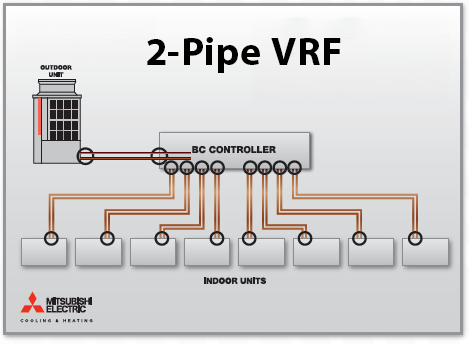

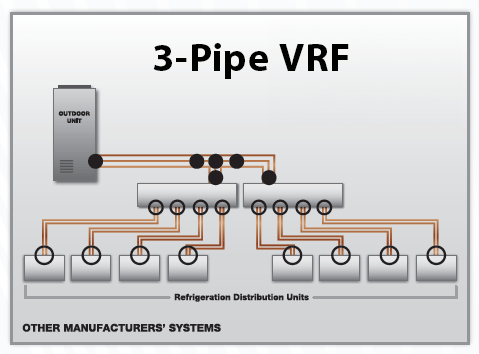

Heat Recovery VRF Systems, available in both 3-pipe versions and 2-pipe versions incorporating separate refrigerant branch controllers (aka box selectors), can provide simultaneous heating and cooling to different areas of a building using a single condensing unit. This makes them ideal for spaces with diverse temperature needs, such as offices, hotels, and hospitals. This also makes them ideal for systems that include both perimeter and interior zones on the same condensing unit.

The system works by transferring heat from zones that require cooling to those that need heating. For example, in one part of the building, the system may be cooling one room by removing heat, while in another area, it can use that excess heat to warm a different room. This process not only optimizes energy use but also enhances overall comfort, as different zones can be customized to individual temperature preferences.

Heat Pump VRF Systems

Unlike Heat Recovery VRF, Heat Pump VRF systems run on a 2-pipe system and are designed to provide either heating or cooling to all zones while connected to a single condensing unit, but not simultaneously. This makes them ideal for zones where the same temperature control is required across all spaces, such as open-plan offices, retail stores, or smaller buildings with similar climate needs throughout. They also work well in moderate climates where the load profile between interior spaces and exterior spaces is not drastically different.

A Heat Pump VRF system operates by distributing refrigerant through a network of two pipes from a single outdoor unit to multiple indoor units, without the need for any branch controllers. The system can switch between heating and cooling modes based on the building’s overall requirements, but it cannot do both simultaneously. While this may limit flexibility in certain settings, it is a simpler, more cost-effective solution for buildings that don’t require varying temperatures in different zones.

However, the limitation of not being able to heat and cool different areas at the same time can be a drawback in buildings with diverse temperature needs. For environments where certain zones might require cooling while others need heating, a Heat Recovery VRF system may be the better choice.

Now, let’s now compare their key differences side by side. Understanding these differences will help clarify the strengths and limitations of each system, so you can make an informed decision based on your building’s specific requirements. Here’s a table highlighting their key features:

| Heat Recovery VRF vs. Heat Pump VRF |

| Feature | Heat Recovery VRF | Heat Pump VRF |

|---|---|---|

| Operational Mode | Simultaneous Heating and Cooling | Heating or Cooling (one mode at a time) |

| Flexibility | Highly flexible; ideal for varying load and temperature requirements | Less flexible; suitable for uniform temperature needs and uniform loads |

| Energy Efficiency | More efficient in diverse settings due to heat recovery capability | Efficient in buildings needing similar temperatures with similar load profiles |

| Installation Cost | Higher initial cost due to 3-pipe configuration or 2-pipe with branch controllers (aka box selectors) | Lower initial cost due to 2-pipe network and no branch controllers or box selectors |

| Maintenance | More complex, requires specialized maintenance | Simpler maintenance |

| Ideal Applications | Hotels, hospitals, multi-use buildings | Open-plan offices, retail stores, homes |

| Occupant Comfort | Personalized comfort in different zones | Personalized comfort as long as all zones agree on the operating mode (Heat/Cool) |

| System Complexity | Complex system with advanced controls to distribute refrigerant | Simpler system with more basic controls |

| Long-term Savings | Greater long-term savings through energy sharing efficiency | Excellent energy savings in more uniform environments |

Factors to Consider When Choosing a VRF System

When deciding between Heat Recovery vs. Heat Pump VRF systems, there are several key factors to keep in mind. The design of your building, usage patterns, the outdoor environment, and long-term operational goals all play an important role in determining which system is the best fit for your building.

Conclusion

Choosing between Heat Recovery and Heat Pump VRF systems ultimately depends on your building’s specific needs, budget, and long-term goals. For buildings with diverse temperature requirements across multiple zones, the flexibility and energy efficiency of Heat Recovery VRF systems may be the best option. Meanwhile, buildings with more uniform heating and cooling demands can benefit from the simplicity and cost-effectiveness of Heat Pump VRF systems.

Both options offer advanced technology that enhances comfort and improves energy efficiency, but the right choice comes down to understanding your building’s unique requirements and the level of control you need over your HVAC system.

Ready to make the right choice for your building?

Contact our team at Schnackel Engineers today to learn more about how Heat Recovery and Heat Pump VRF systems can transform your building’s efficiency and comfort. Our HVAC experts are here to guide you through the decision-making process and ensure you select the ideal solution for your space.

The post Heat Recovery vs. Heat Pump VRF Systems: What’s the Difference? appeared first on Melissa Test Site.

]]>The post HVAC Humidity Control: 4 Tactics for the Florida Environment appeared first on Melissa Test Site.

]]>This blog covers four common strategies for controlling HVAC humidity in environments like Florida.

Understanding Humidity in Florida’s Buildings

Humidity refers to the amount of moisture in the air. In Florida, maintaining proper humidity levels inside buildings is essential due to several factors:

Occupant Comfort

Florida’s high humidity levels can make indoor environments feel warmer, “stuffy”, and uncomfortable. As a result, occupants often adjust thermostats to lower temperatures to compensate, leading to increased energy use.

Mold Growth

The warm and humid climate in Florida fosters mold and mildew growth, which can damage building materials and pose health risks to occupants. Effective humidity control is essential to mitigate these issues.

Material Integrity

Excess moisture can adversely affect building materials such as wood, drywall, and insulation, causing them to warp, rot, and suffer structural damage. Maintaining proper humidity levels helps preserve the integrity of these materials.

Operational Issues

High humidity also impacts the operation of equipment inside the building, including printers and other paper handling equipment, causing jambs and poor quality prints.

HVAC Efficiency

High humidity places additional strain on HVAC systems, resulting in longer operating hours and more frequent maintenance and repairs. Proper humidity management is crucial for maintaining system performance and longevity.

Four HVAC Humidity Control Tactics for Florida’s Commercial Buildings

Managing humidity in Florida’s commercial and residential buildings is crucial due to the state’s warm and humid climate. Proper humidity control ensures occupant comfort, prevents mold growth, preserves building materials, and maintains HVAC system efficiency. Here are four effective HVAC humidity control tactics for managing humidity in commercial spaces:

Tactic 1: Dehumidification Systems

Dehumidifiers are specialized devices designed to remove excess moisture from the air, making them essential for humidity control in interior spaces. Integrating these systems with existing HVAC units can greatly enhance their effectiveness.

There are two main types of dehumidifiers used in commercial settings: standalone dehumidifiers and integrated dehumidifiers.

Standalone dehumidifiers are placed in specific zones with particularly high humidity levels. They contain their own fans and dehumidification equipment. They typically dehumidify using either refrigeration circuits with reheat coils or desiccant dehumidification systems that actually absorb the humidity from the room air and reject it to the outdoor environment. Dedicated dehumidification equipment is quite expensive and is typically only applied when integrated dehumidification systems are not sufficient to address the humidity control problem. Standalone dehumidifiers are also very useful in retrofit applications, where the existing HVAC system is incapable of providing the necessary dehumidification capacity.

Integrated dehumidifiers work with the HVAC system to manage humidity throughout the entire building. They often utilize the same refrigeration circuits that provide air conditioning to the space and efficiently use the condenser heat rejection to provide the necessary reheat to prevent overcooling the space. Integrated dehumidification is generally applied only at the initial design and construction phase, because they must be designed into the overall HVAC concepts in order to be effective.

Using dehumidification systems helps buildings maintain comfortable humidity levels, reducing the risk of mold growth and protecting building materials and operations.

Tactic 2: Variable Speed Air Handlers

Variable speed air handlers are an effective solution for managing humidity in commercial spaces. Unlike traditional single-speed units, these air handlers adjust their speed to match the building’s cooling and dehumidification needs, allowing for more precise control of humidity levels.

These systems vary the speed of the fans and compressors to allow the system to maintain the necessary low-coil surface temperatures necessary to remove humidity. They are very energy efficient, consuming less power by operating at lower speeds when full capacity isn’t needed. They also improve comfort by maintaining more consistent temperature and humidity levels.

By implementing variable speed air handlers, building owners can achieve better humidity control while saving on energy costs.

Tactic 3: Energy Recovery Ventilators (ERVs)

ERVs improve indoor air quality while helping to control humidity. They bring in fresh outdoor air and remove stale indoor air, transferring the heat and moisture between the two air streams to maintain lower incoming air humidity and temperature levels than with direct outdoor air intake systems.

ERVs enhance air quality by introducing fresh air while improving humidity control and saving energy. Additionally, by transferring heat and moisture, ERVs reduce the load on HVAC systems, leading to energy savings and reduced capacity equipment. ERVs make sense whenever there is a sufficient supply of building exhaust air to allow for efficient energy recovery and transfer to the incoming air stream.

ERVs offer a comprehensive solution for managing humidity and improving indoor air quality in commercial and residential spaces.

Tactic 4: High-Efficiency HVAC Units

Upgrading to higher-efficiency HVAC units, with integrated dehumidification cycles, is another sensible way to improve humidity control. These systems operate more efficiently, offering better temperature and humidity regulation. They can be specified with integrated dehumidification cycles that recover the waste heat of the compressor/condenser cycle to provide the reheat necessary to prevent space overcooling during high humidity conditions.

High-efficiency HVAC units have advanced features that enhance performance and humidity control. They also have lower operating costs because they consume less energy, resulting in reduced utility bills.

High-efficiency HVAC units ensure optimal humidity control and cost savings for many building types, in Florida and around the country.

Best Practices for Implementing HVAC Community Control Tactics

To get the most out of these HVAC humidity control tactics, follow these best practices:

Regular Maintenance

Consistent maintenance of HVAC systems is vital for optimal humidity control. Regularly replace filters to maintain proper airflow and system efficiency. Clean coils frequently to enhance heat exchange and moisture removal. Inspect and clean ducts to prevent mold and mildew accumulation.

Proper Insulation and Sealing

Effective insulation and sealing of the building envelope are crucial for managing humidity. Utilize high-quality insulation materials, with continuous vapor barriers, to prevent moisture infiltration. Seal gaps and cracks around windows, doors, and other openings to block moisture entry effectively.

Humidity Monitoring

Install humidity sensors and monitoring systems to keep track of humidity levels in real-time. Automated systems can adjust HVAC settings based on the real-time data, ensuring optimal humidity levels with minimum operating cost. Set up alerts for unusual humidity levels to enable prompt intervention.

Educating Occupants

Educate building occupants about the importance of humidity control and how they can contribute. Encourage efficient use of the building systems, including proper use of doors, windows, and infiltration control systems. Encourage prompt reporting of any signs of moisture or mold so the systems can be adjusted quickly, before permanent damage occurs.

Conclusion

Effective humidity control is essential for maintaining comfortable and healthy environments in Florida’s indoor spaces. Building owners and facility managers can control humidity by using advanced HVAC solutions. These solutions include dehumidification cycles, variable speed air handlers, ERVs, and high-efficiency HVAC units. Achieving optimal humidity control is possible with these technologies.

Regular maintenance, proper insulation, and humidity monitoring further enhance these efforts, ensuring a productive and pleasant indoor environment.

If you need help with HVAC humidity control in your building or space in Florida, reach out to Schnackel Engineers. Our team of MEP engineers in Miami can create comfortable and efficient environments tailored to Florida’s climate. Contact us to discuss your project and learn how we can help manage humidity in your building.

The post HVAC Humidity Control: 4 Tactics for the Florida Environment appeared first on Melissa Test Site.

]]>The post Common Electrical Code Violations: Tips for Building Owners appeared first on Melissa Test Site.

]]>Electrical Code Compliance: Why It Matters

Electrical code compliance is critical in ensuring the safety and functionality of electrical installations, particularly in commercial buildings where electrical requirements are complex and the stakes are high. Compliance involves adhering to the standards set by the National Electrical Code (NEC), which is regularly updated to reflect the latest in safety practices and technological advancements. This set of guidelines is designed to prevent hazards that could lead to electrical fires, failures, and accidents, thereby protecting both people and property.

In commercial properties, the implications of not following the NEC can range from minor issues, like improperly labeled circuits, to major risks, such as inadequate wiring that fails to support the building’s electrical load. These violations can lead to serious safety hazards, including increased risk of fire and electrocution. Moreover, non-compliance can often result in significant legal and financial consequences. Penalties may include fines, legal actions, and increased insurance premiums, not to mention the potential for severe operational disruptions that could impact business continuity and revenue.

Most Common Electrical Code Violations in Commercial Buildings

- Inadequate Wiring and Protection: Using wiring that is not suitable for the current demand, or failing to protect wiring adequately, can lead to overheating and electrical fires.

- Loose Connections and Overheating Equipment: How tightly the wiring is fastened to equipment and breakers has a significant impact on the fire safety of the system, especially when using aluminum wiring. Connections that are either too loose, or too tight in the case of aluminum wiring, cause arcing and severe heating of the cables and connectors.

- Improper Grounding: A properly grounded electrical system helps stabilize system voltage levels and clear faults quickly and safely. Improper grounding can result in a serious risk of electric shock or fires.

- Lack of GFCI Protection: Ground Fault Circuit Interrupters (GFCI) are required in areas where electricity is likely to come into contact with water (like kitchens and bathrooms). Not installing GFCI protection is a common violation that can lead to electrical shocks.

- Faulty Electrical Panels: Old or improperly installed electrical panels can fail to handle the energy demands of modern commercial operations, leading to outages and fire hazards.

- Lack of Working Space around Electrical Equipment: Storing items too close to electrical panels, switchgear, and other equipment can obstruct the required clearance and working space needed for safe operation and maintenance.

- Inadequate Interrupting Ratings: Utility company services have the potential to deliver tremendous amounts of energy in a fault condition. Equipment must be rated and braced for the potential current flow in the event of a fault.

Each of these violations not only poses a risk to safety but also affects the operational efficiency of a commercial property. Regular inspections and understanding the specific requirements of the NEC can help mitigate these risks.

Consequences of Ignoring Electrical Code Violations

Ignoring electrical code violations in commercial buildings can have serious repercussions, extending far beyond the immediate risks of fines and penalties. Here are some of the critical consequences that building owners need to be aware of:

- Safety Hazards: The most direct consequence of code violations is the increased risk of safety hazards, such as electrical fires and electrocutions. These incidents can lead to severe injuries or even fatalities, making compliance a matter of life and death. Arc flash and fault current risks are among the most devastating of electrical system failures.

- Legal and Insurance Implications: Non-compliance can result in hefty fines and possible legal actions from local authorities. Additionally, insurance claims may be denied if it is found that the incident was due to negligence in adhering to electrical codes, leading to significant financial losses.

- Operational Disruptions: Electrical problems can cause unexpected downtime, affecting business operations and resulting in lost revenue. For instance, a major electrical failure could shut down production lines, affect HVAC systems, or disrupt other critical business activities.

- Reputation Damage: Safety incidents or operational failures due to electrical issues can harm a business’s reputation. A well-publicized incident can erode trust among customers and partners, potentially leading to long-term negative impacts on the business.

- Increased Maintenance Costs: Ignoring minor violations can lead to larger problems over time, necessitating more extensive and expensive repairs. Proactive maintenance and compliance can significantly reduce these costs by addressing issues before they escalate.

Understanding these consequences underscores the importance of regular electrical inspections and immediate action on any identified violations. Ensuring compliance with electrical codes is not just a regulatory requirement—it’s a critical investment in the safety and sustainability of a business.

How Building Owners Can Avoid Electrical Code Violations

Ensuring that your commercial property adheres to electrical codes not only boosts safety but also enhances operational efficiency. Here are several actionable tips that building owners can implement to maintain electrical compliance:

- Regular Inspections and Audits: Schedule regular inspections with properly licensed electricians who specialize in commercial properties. These professionals can identify potential violations and recommend corrective actions before they turn into major issues.

- Consult with Electrical Engineers: Collaborating with electrical engineers can provide an additional layer of expertise, particularly for complex projects or large commercial properties. These professionals can design and evaluate electrical systems to ensure they meet both current needs and regulatory standards, offering solutions that optimize safety and efficiency.

- Have an Arc-Flash Study Completed for Your Property: Arc flash studies provide valuable information about the hazards in an electrical system and how to mitigate those risks with respect to personnel protection and operational safety procedures.

- Hire Qualified Electrical Contractors: Always work with licensed and experienced contractors for any installation, repair, or renovation work. Qualified professionals understand the intricacies of the NEC and will ensure that all work complies with the latest safety standards.

- Update and Upgrade Electrical Systems: As building operations evolve and electrical demands increase, it’s crucial to ensure that your electrical systems are up to date. This might involve upgrading wiring, panels, and safety devices to handle increased loads and meet current safety standards.

- Educate Your Team: Make sure that your facility managers and maintenance staff are knowledgeable about basic electrical safety and compliance. Regular training sessions can help staff recognize potential electrical hazards and understand the importance of code compliance. This is where arc flash studies are crucial. They identify and label all equipment with the required PPE (personal protection equipment) necessary to safely perform maintenance on the systems.

- Implement a Compliance Checklist: Develop a comprehensive checklist based on the NEC and local codes that covers all aspects of your electrical system. Regularly review and update the checklist to ensure ongoing compliance.

- Address Violations Promptly: If inspections reveal any code violations, address them immediately. Delaying corrective action can lead to the issues mentioned in the previous section, including safety risks and potential fines.

By following these tips, building owners can significantly reduce the risk of electrical code violations and create a safer environment for everyone using the property.

Bottom Line

Electrical code violations pose significant risks to commercial properties, impacting safety, legality, and operational integrity. As a building owner, it’s crucial to understand these violations and implement measures to prevent them.

At Schnackel Engineers, we provide expert guidance on electrical codes, arc flash studies and overall MEP system optimization to help ensure your property meets all safety standards. Contact us today to see how we can assist you in maintaining a compliant, efficient, and safe environment.

The post Common Electrical Code Violations: Tips for Building Owners appeared first on Melissa Test Site.

]]>The post Optimizing New York City’s AEC Industry: The AI Advantage appeared first on Melissa Test Site.

]]>Common Challenges in the AEC Sector

The AEC(Architectural, Engineering, and Construction) sector is no stranger to challenges. Inflation and high interest rates have been a persistent issue, driving up the costs of materials and labor, which in turn affects project budgets. Supply chain disruptions, often due to global events or trade issues, lead to delays and increased costs. Labor shortages, a result of a dwindling skilled workforce, further exacerbates project timelines, budgets, and quality. Additionally, there’s a noticeable reluctance within the industry to adopt new technologies, with many preferring to stick to traditional methods or “the way we have always done it”. This resistance to change hinders innovation and efficiency.

The Rise of AI in Various Industries

Artificial Intelligence has already made a significant impact in various industries, demonstrating its potential to transform operations and outcomes. In healthcare, AI is used for predictive analytics, personalized medicine, and streamlining administrative tasks. The finance sector leverages AI for fraud detection, risk management, and automated trading. In IT, AI enhances cybersecurity and data analysis. Manufacturing benefits from AI through improved production efficiency and quality control.

These industry breakthroughs not only affirm AI’s transformative capabilities but also build a trust in its applicability across diverse fields. This growing confidence in AI sets a promising backdrop for its integration into more traditionally conservative sectors like the Architecture, Engineering, and Construction (AEC) industry. Despite a slower start in digital adoption, the AEC sector is on the cusp of a technological revolution, with AI at the forefront.

The growing interest in AI within the AEC industry marks a significant shift, indicating the sector’s readiness to use AI for addressing complex challenges. From improving project management to transforming design and increasing onsite safety, AI’s potential uses in the AEC sector are wide-ranging.

As we move to the next section, we will explore the specific AI technologies that are making a significant impact within the AEC industry. This exploration will show how AI is not just a tool for improving operations but a transformative force that is reshaping the fields of design, construction, and urban planning, leading to a new era of smart, sustainable, and efficient urban development.

Application of AI Tools in the AEC Industry

AI’s entry into the AEC industry is characterized by innovative applications that tackle specific challenges:

AI in Architectural Design

In architectural design, AI is revolutionizing the way architects approach their projects, offering innovative solutions that enhance both the creative and practical aspects of design.

AI-powered tools, such as 3D imaging, are accelerating the creation and refinement of complex models, enabling architects to quickly develop intricate façades and structures with precision. This technology not only enhances the speed and accuracy of the design process but also allows for greater experimentation and innovation.

by Adidas Brand Center – Shenzhen, China

Design ideation is another area where AI is making a significant impact in architectural design. By analyzing patterns, trends, and historical data, AI assists architects in generating innovative design concepts, pushing the boundaries of creativity. AI-powered image generation tools, like Midjourney, exemplify this by enabling architects to explore new design options quickly and efficiently. By entering specific prompts, architects can leverage AI to create multiple iterations of building designs, breaking away from traditional approaches and generating fresh ideas.

Moreover, in space planning, AI’s capabilities are invaluable, offering sophisticated insights to ensure floor plans are both aesthetically pleasing and operationally efficient. This technology considers the day-to-day functional needs and spatial relationships, aiming to support the operational effectiveness of the tenant’s business. For instance, qbiq, an AI software designed for efficient office planning, offers architects three ‘test fit’ options, each with analytical furniture layouts and 3D virtual tours, accompanied by a performance analysis report, to optimize the design process.

Furthermore, AI-driven tools are enabling architects to address sustainability challenges more effectively. By analyzing environmental data and simulating building performance, AI helps in designing energy-efficient buildings that reduce carbon footprints and promote environmental stewardship.

Overall, the integration of AI in architectural design is transforming the industry, making it possible to achieve higher levels of innovation, efficiency, and sustainability. As AI technology continues to evolve, it is poised to unlock even more possibilities in the realm of architectural design, shaping the future of our built environment.

AI in MEP Engineering Design

AI is transforming MEP engineering, streamlining complex processes, and enhancing precision and efficiency. AI serves as a powerful analytical engine, quickly navigating through numerous design solutions to identify the most optimized approaches, while ensuring compliance with stringent regulations.

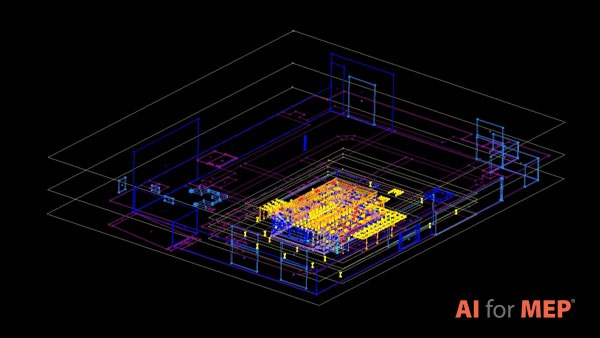

AI-driven design automation software, such as AI for MEP®, revolutionizes how MEP systems are conceptualized, significantly reducing design time and construction costs, while improving accuracy and compliance. This technology enables rapid iteration of design solutions, optimizing systems for energy efficiency, cost, and performance.

AI for MEP® by Schnackel Engineers

AI also plays a crucial role in predictive maintenance within MEP systems. By continuously analyzing data from sensors and IoT devices, AI can predict system failures before they occur, schedule timely maintenance, and suggest improvements for future operations, leading to reduced downtime, lower maintenance costs, improved energy efficiency, and longer system lifespans.

In summary, AI is a transformative force in MEP engineering, offering robust solutions that carry projects from the drawing board to completion with greater speed, accuracy, and innovation. As New York City continues to grow, embracing AI in MEP design will be crucial for constructing buildings that are efficient, sustainable, and future-proof.

AI in Construction

In the construction phase, AI is dramatically reshaping efficiency, safety, and quality control. Factory based, automated modular construction techniques result in improved quality, quicker construction, and reduced cost. Robotics and automation, featuring automated surveying and grading equipment, brick-laying robots, and concrete printing machines, are becoming more common on job sites, reducing manual labor, while enhancing precision and safety. These innovations not only speed up construction but also open up new possibilities for complex structures that were once too costly or challenging to build.

In project management, AI-driven tools are optimizing construction scheduling, ensuring projects stay on track and within budget.

Quality control is another area where AI excels, with automated systems monitoring the work for adherence to the design documents, industry standards, and construction specifications.

Job site safety is a top priority, and AI is instrumental in monitoring work environments to identify potential hazards, and safety policy violations, thereby preventing accidents and ensuring the well-being of workers.

Through these innovations, AI is not just an auxiliary tool but a central component in modern construction practices, driving the industry toward a future where projects are safer, more efficient, and of higher quality.

Don’t Fear AI – Embrace It!

There’s a common apprehension toward AI in any industry, often rooted in concerns about job displacement and fear of the unknown. However, AI’s purpose is not to replace human expertise, but rather to augment it by eliminating monotonous tasks. By automating routine tasks, AI allows professionals to concentrate on the more strategic and creative aspects of their work.

Embracing AI technology is about embracing a future of greater efficiency, accuracy, and innovation. It’s time to see AI as an ally, not a threat, in building a smarter, more sustainable urban environment.

Adopting Artificial Intelligence (AI) is becoming essential for optimizing New York City’s AEC industry. AI’s impact on architectural design, MEP engineering, and construction is significant, enhancing efficiency, safety, and sustainability. As new AI technology evolves, it is increasingly shaping the future of urban development and establishing new benchmarks for the industry.

However, not embracing AI can lead to missed opportunities for innovation and lost competitive advantage, leaving firms behind in an increasingly technology-driven market. The future of AI in the AEC industry is promising, with potential for even greater advancements in automation, data analysis, and design innovation. This continued evolution will further revolutionize the way buildings are designed, constructed, and maintained.

At Schnackel Engineers, we’re harnessing AI to optimize your projects. Our experienced MEP/FP engineers in our New York office, equipped with the firm’s proprietary AI for MEP® software, are ready to help you leverage the benefits of AI, ensuring your projects are completed with greater speed, accuracy, and quality. Contact us to discover how we can assist in optimizing your projects with AI for a more successful outcome.

The post Optimizing New York City’s AEC Industry: The AI Advantage appeared first on Melissa Test Site.

]]>The post Exploring the Fundamentals of Lighting Control Systems appeared first on Melissa Test Site.

]]>The Importance of Quality Lighting in Buildings

Quality lighting is crucial for fostering comfortable, productive, and safe environments. It not only accentuates architectural details but also influences mood and can have profound effects on the health and well-being of occupants. In commercial spaces, effective lighting enhances branding and the customer experience, while in residential areas, it improves the ambiance and functionality of each room.

However, lighting is also a major consumer of energy. Therefore, a well-designed and efficiently controlled lighting system is vital for reducing operational costs and lessening environmental impact.

Understanding Lighting Control Systems

A lighting control system is an interconnected network of devices and software that enables users to modify and regulate the illumination levels within a space. These systems range from basic manual switches to advanced automated setups that seamlessly integrate with other building management systems. Even a simple wall switch is a form of lighting control; however, this blog focuses on more complex lighting control systems that are able to operate multiple lights, multiple zones, and provide multiple settings.

The primary aim is to deliver the appropriate amount of light exactly when and where it’s needed, optimizing comfort and energy usage.

How Lighting Control Systems Operate

These systems utilize touch panels, sensors, timers, and controllers to dictate the activation and deactivation of lights. By adjusting illumination based on occupancy, natural daylight, or predefined schedules, lighting control systems ensure energy is only used when necessary. This approach not only saves energy but also lowers costs and extends the lifespan of lighting fixtures.

Modern systems offer local, centralized, or remote control options via smart devices, adding flexibility and convenience to lighting management.

Lighting control systems are designed to cater to specific requirements and preferences. Common types include:

| Lighting Control Type | Description | Common Applications |

|---|---|---|

| Manual Controls | Simple on/off switches and dimmers that allow manual light adjustment for individual light fixtures or groups. | Institutions, Healthcare Facilities, Retail, Restaurant, Residential, Religious Buildings, Schools. |

| Dimmers | Enable brightness adjustment, enhancing control over ambiance and energy usage. | Art Galleries, Auditoriums, Libraries, Museums, Conference Rooms, Hospitality, Residential, Restaurants, Theaters, Entertainment. |

| Occupancy Sensors | Automatically control lights based on the presence of people. | Healthcare Facilities, Offices, Meeting Spaces, Parking Garages, Restrooms, Retail Stores, Storage Rooms, Hallways, Warehouses . |

| Daylight Harvesting Controls | Adjust indoor lighting according to natural light availability, maximizing energy efficiency. | Office Spaces, Schools, Retail, Healthcare Facilities, Industrial, Residential. |

| Time-based Controls | Schedule lighting for security and efficiency. Ensures lights are on only when needed. | Street Lighting, Landscape Lighting, Building Exterior. Often used as a master switch for other building occupancies like Restaurants and Retail Stores. |

| Centralized Lighting Control Systems | These comprehensive systems allow for the management of all lighting fixtures from a single or multiple interfaces. Allows for complex programming and large installations. | Commercial, Educational Institutions, Healthcare Facilities, Hospitality, Industrial, Large Office Buildings, Malls, Outdoor. |

| Smart Lighting Controls | Utilize internet connectivity for remote access and advanced features, adapting to usage patterns for optimal performance. Most Distributed and Centralized Lighting Control Systems have smart device interfaces. | Same applications as Distributed and Centralized Lighting Control Systems. |

Advantages of Lighting Control Systems

Implementing a lighting control system in a building offers a multitude of advantages that extend beyond simple convenience. These systems not only contribute to a more sustainable environment but also have a significant impact on the bottom line, comfort, and productivity.

Energy Efficiency

Lighting accounts for a substantial portion of energy consumption in buildings. The U.S. Energy Information Administration reports that lighting represents close to 17 percent of total electricity consumption in commercial buildings across the U.S. By ensuring that lights are used only when needed, lighting control systems can significantly reduce this energy consumption.

By implementing advanced lighting control strategies, such as occupancy sensing and daylight harvesting, buildings can significantly lower their energy usage and associated costs.

Cost Savings

The energy efficiency of lighting control systems directly translates to cost savings. Reduced energy consumption leads to lower utility bills, resulting in substantial savings over time.

In addition to direct energy savings, financial incentives may be available from utility companies or government entities for implementing energy-efficient lighting solutions, including lighting control systems.

Furthermore, lighting control systems can lead to reduced maintenance costs by optimizing the use of lighting fixtures and extending their lifespan. This not only saves on direct maintenance expenses but also minimizes disruptions and downtime associated with lighting maintenance, further enhancing operational efficiency.

Enhanced Comfort

Lighting control systems offer the flexibility to adjust lighting levels to suit different activities, moods, and preferences. This can significantly improve the comfort of occupants. For example, dimmable lighting can create a more relaxed atmosphere in a restaurant or a more focused environment in a conference room.

The ability to personalize lighting settings can also contribute to a sense of well-being and satisfaction among building occupants.

Improved Productivity

Proper lighting is essential for maintaining concentration and productivity, especially in workspaces.

Poor lighting conditions can significantly impact cognitive performance and alertness.

Good lighting design, including access to natural light and appropriate lighting controls, can improve productivity. Well-lit environments help reduce eye strain and fatigue, leading to a more focused and efficient workforce.

Sustainability

Lighting control systems contribute to environmental sustainability by reducing energy consumption.

Lower energy use results in fewer greenhouse gas emissions, which is crucial in the fight against climate change. Energy efficiency improvements in lighting have played a significant role in reducing global carbon dioxide emissions.

By implementing lighting control systems, buildings can significantly reduce their carbon footprint, contributing to a more sustainable future.

Security

Lighting control systems can enhance building security by providing well-lit environments during off-hours or in response to security alerts. Automated lighting can deter intruders and provide better visibility for surveillance systems.

Integration with Smart Building Systems

Modern lighting control systems can be integrated with other building management systems, such as HVAC and security, to create a cohesive and intelligent building ecosystem. This integration can lead to even greater energy savings and operational efficiencies.

Bottom Line

Lighting control systems are crucial for modern, sustainable, and efficient building design. They blend functionality with aesthetics, offering significant benefits for architects and building owners. Through their implementation, we contribute to creating environments where people can thrive, underscoring the importance of smart, energy-conscious design in modern living and working spaces.

Considering integrating advanced lighting control solutions in your projects? Schnackel Engineers, along with our subsidiary, Light Plan Design, specialize in integrated cutting-edge lighting design and control, ready to transform your spaces into visually stunning, environmentally friendly, and cost-efficient environments. Contact us to light up your next project with innovation and sustainability.

Note: mls312/staging

The post Exploring the Fundamentals of Lighting Control Systems appeared first on Melissa Test Site.

]]>The post Decarbonizing Nebraska with Advanced MEP Strategies appeared first on Melissa Test Site.

]]>The building sector, a notable contributor to the state’s carbon emissions, faces the urgent need to transition towards sustainability. This journey is not merely about adhering to new standards but re-envisioning construction and design to be in harmony with our environment. Central to this evolution are advanced MEP (mechanical, electrical, and plumbing) strategies, offering a roadmap for decarbonization that promises environmental preservation and heralds a new era of sustainable development across the great State of Nebraska.

Understanding Building Decarbonization