What is the Difference Between 2-Pipe and 3-Pipe VRF Systems?

Variable Refrigerant Flow (VRF) systems have emerged as a leading solution for climate control in diverse building types within the HVAC industry. Renowned for their versatility, small size, and energy efficiency, VRF systems depart from traditional centralized air conditioning, providing an adaptable and zone-specific approach to temperature control. Two distinct configurations exist within the VRF industry: 2-pipe and 3-pipe systems. Choosing between them can be complex, and understanding their fundamental differences is crucial for achieving optimal results in your next project. In this blog, we’ll discuss the basic differences between 2-pipe and 3-pipe VRF systems, with the aim of guiding you towards well-informed decisions that align seamlessly with their project requirements.

What exactly is a VRF system?

A VRF system, or Variable Refrigerant Flow system, is a modern HVAC solution that differs from traditional systems in its design and operation. Instead of relying on bulky ductwork and central air handlers, VRF systems utilize a network of refrigerant lines that connect a single outdoor unit to multiple individual fan coil units (FCUs) spread throughout the building. These FCUs function as independent climate controllers, allowing for precise temperature and airflow adjustments in specific zones with separate thermostats for each zone. This decentralized approach offers numerous advantages over traditional HVAC systems.

One key advantage is zoning flexibility. With a VRF system, users have precise control over individual zones, maximizing comfort levels and minimizing energy waste in unoccupied areas. VRF FCUs are relatively small and allow for more individual zones of control within the area served.

Additionally, VRF systems are highly efficient due to their variable refrigerant flow capabilities, which enable precise matching of cooling or heating demands. This results in significant energy savings compared to traditional systems.

Another benefit is quiet operation. Because VRF systems do not require indoor compressors or extensive ductwork, they produce minimal noise, creating a quieter, more peaceful indoor environment.

Additionally, the small and modular nature of VRF systems offers design flexibility, making them easy to install and adapt to existing structures. This versatility enhances the system’s overall efficiency and effectiveness in meeting the building’s HVAC needs.

Exploring the Two Main Piping Configurations for VRF Systems

When it comes to VRF (Variable Refrigerant Flow) systems, there are two main piping configurations to consider. Both systems are capable of providing simultaneous heating and cooling.

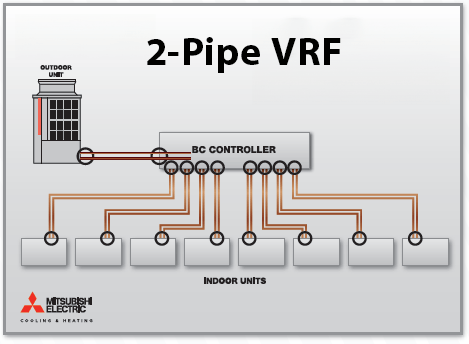

2-Pipe VRF Systems

In a two-pipe system the outdoor unit is connected with two pipes to a device called a branch circuit controller. The branch circuit controller, in turn, distributes the refrigerant to each fan coil unit using two pipes also.

The simplicity of the two-pipe system has advantages. The indoor unit capacity determines the size of the lines between the branch circuit controller and the indoor unit. This means, that should the outdoor unit capacity change, the pipes downstream of the branch circuit controller can remain if the fan coils remain and minor changes to the layout of the system do not change the pipe diameters.

Because the refrigerant lines from the outdoor unit to the branch controller are determined by the outdoor unit capacity, layout changes upstream of the branch controller also do not affect pipe diameters. This flexibility is a significant advantage for projects that may encounter changes during construction or down the road.

Another advantage is the indoor units can quickly change from heating to cooling.

The main disadvantage of a 2-pipe VRF system is cost. In some instances, because of the need for branch circuit controllers, longer refrigerant lines may be needed to reach the fan coils adding to material cost and labor when compared to three-pipe systems.

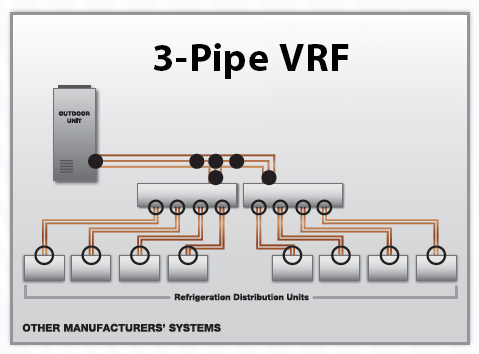

3-Pipe VRF Systems

In order to provide simultaneous heating and cooling, these systems use three pipes to deliver the refrigerant in the appropriate state to the fan coils. This is because the phase separation (heating vs. cooling) occurs at the outdoor unit as opposed to the main branch controller in two-pipe systems.

Three-pipe systems usually require less piping overall, meaning potential construction cost savings. However, three-pipe systems are less flexible than two-pipe systems. Any changes after the system design affect the system overall and pipe designs must be re-calculated. This can make any changes very costly if piping has already been installed. This also limits the future flexibility of the system without potential replacement of the existing refrigerant lines.

The Verdict: Matching Your Needs to the Perfect VRF System

Choosing between 2-pipe and 3-pipe VRF systems boils down to a careful analysis of your project’s specific requirements. Here are some key factors to consider:

Building Size and Zoning Needs

In the decision-making process, the size of your building and zoning intricacies play a pivotal role. Smaller buildings or those with minimal zoning complexity can benefit significantly from the cost-effectiveness of a 3-pipe system. Buildings that may require changes after design benefit from the adaptability inherent in a 2-pipe system.

Climate Demands

The nature of climate demands is a crucial consideration. Projects characterized by frequent simultaneous heating and cooling needs will find the flexibility of a 3-pipe system particularly well-suited to meet such demands effectively.

Available Space

The branch controllers of a 2-pipe system require significant space inside the building. This can be particularly challenging in existing buildings or new buildings with limited mechanical space available. The 3-pipe system does not require branch controllers, therefore may be easier to fit into the constraints of the building.

Budget Considerations

The cost of each system is heavily dependent on specific building conditions. Therefore, a careful analysis of the building requirements is necessary to make a good decision. Budget considerations are integral to the decision-making equation. While it is highly variable, 3-pipe systems generally present lower upfront costs due to reduced copper line set lengths, making them an attractive option for projects with budget constraints. On the other hand, 2-pipe systems require a higher initial investment but may translate into long-term savings due to their flexibility and ability to be adapted to changes.

In essence, the verdict on choosing the perfect VRF system for your needs hinges on a comprehensive evaluation of building size, zoning intricacies, climate demands, and budget constraints. By carefully weighing these factors, you can make an informed decision that aligns seamlessly with the unique requirements of your project.

Conclusion

When it comes to selecting the ideal VRF system for your project, it’s essential to weigh the specific requirements carefully. Consider factors such as building size, zoning needs, climate demands, and budget constraints to make an informed decision. Whether opting for the cost-effective and adaptable 2-pipe system or the capabilities of the 3-pipe configuration, ensure that your choice aligns seamlessly with your project’s unique needs.

For personalized guidance and support in choosing the most suitable VRF system for your project, turn to Schnackel Engineers. With our wealth of experience and forward-thinking approach in mechanical system design, we provide customized HVAC solutions that optimize efficiency, comfort, and cost-effectiveness. Reach out to us today to discover how we can assist you in selecting and implementing the most optimal VRF system for your requirements.

Comments

Comments are closed.