Energy Recovery Ventilators (ERVs)

In today’s energy-conscious world, businesses are constantly seeking ways to reduce their environmental impact and operating costs. Energy recovery ventilators (ERVs) offer a compelling solution to both of these challenges. This blog post delves into the intricacies of ERVs, exploring their benefits and considerations for commercial building owners. Whether you’re seeking to enhance your building’s sustainability or simply improve indoor comfort, this guide will equip you with the knowledge necessary to make informed decisions about ERV implementation.

What is an energy recovery ventilator?

An energy recovery ventilator (ERV) is a piece of equipment that extracts energy from the airflow that is removed from a building, and uses that energy to pre-condition outdoor air which is brought into the building. During the summer months, cooler/dryer air removed from the building is used to pre-cool and reduce the humidity of the warm, moist outdoor air. During the winter months, the warmer/moister air from the building pre-heats and humidifies the colder, dryer outdoor air before it is delivered to the building or space.

How does an energy recovery ventilator work?

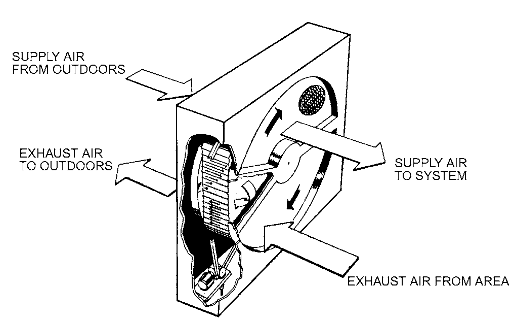

The ERV contains an enthalpy (heat and moisture) recovery wheel that slowly rotates through the supply and exhaust air streams. The wheel is typically constructed of a polymer material with a desiccant (drying agent) bonded to the surface. As the wheel rotates, the desiccant picks up moisture from the higher humidity airstream and deposits the moisture in the lower humidity air stream. Likewise, the wheel absorbs heat from the higher temperature airstream and releases the heat to lower temperature airstream. A simple diagram of an ERV wheel is indicated below.

Code Requirements

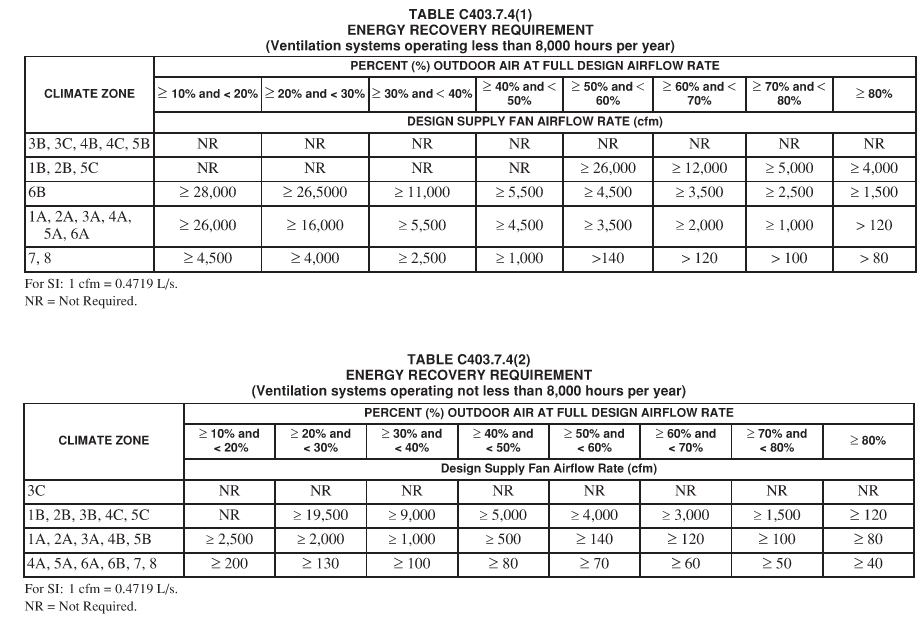

Energy recovery ventilation systems are mandatory in most national energy codes (International Energy Conservation Code, ASHRAE 90.1) ; however, the requirements vary based upon a number of factors:

- Project location (climate zone)

- Supply air quantity

- Percentage of outdoor air to supply air

- Number of system operation hours per year

In general, the codes will require energy recovery for any 100 percent outdoor air systems for projects located within a vast majority of the country. See the tables below from the 2018 International Energy Conservation Code (IECC) for an example of when energy recover systems will be required.

Why should I consider using an ERV?

Advantages

- Reduced size of HVAC equipment

- The HVAC equipment that conditions the spaces may be downsized due to the reduction in heating and cooling load resulting from usage of an ERV system. The ERV preconditions the outdoor air, so the space conditioning HVAC equipment does not need to include the heating/cooling capacity necessary to treat the outdoor air, resulting in lower capacity system requirements.

- Improved indoor air quality and better humidity control

- The ERV provides filtered, pre-conditioned air to the HVAC equipment that serves the spaces. During the summer the outdoor air humidity is reduced by the ERV, while during the winter, moisture is introduced to the outdoor air stream from the outgoing exhausted air. This allows for a greater level of humidity control than if the outdoor air was directly introduced to the interior equipment.

- Electrical and gas demand reduction during cooling and heating seasons

- The preconditioning of the outdoor air by the ERV system results in reduced electrical demand during the cooling season. The HVAC equipment size reductions and the reduced energy required by the space conditioning HVAC equipment can lead to substantial energy savings. Similarly, the heating demand is also reduced during wintertime operation of the wheel by means of the heat and moisture transferred by the ERV wheel.

Disadvantages

- Maintenance

- Energy Recovery Ventilators require periodic maintenance. The air filters need to be changed regularly to prevent dirt buildup on the wheel, causing excessive pressure drop and an associated increased fan energy usage. The energy wheel also needs to be occasionally removed and washed to maintain peak efficiency. The frequency of the filter changes and wheel washing is dependent on the quality of the airstreams through both sides of the ERV system since both airstreams impact the cleanliness of the wheel. Higher efficiency filters can offset some of the wheel cleaning requirement, when properly applied, also resulting in cleaner air entering the building.

- Physical Space Requirements

- Energy Recovery Ventilators can be located on the exterior of the building (roof), or within the building in a ceiling space or mechanical room. The engineer and building designer should collaborate to find the best solution to meet the project requirements. Service clearances need to be carefully reviewed to ensure adequate space is provided for periodic maintenance.

- Airflow Carryover

- Energy wheel type ERVs are not suitable for all project types. Because the energy wheel rotates through both the exhaust air and outdoor air, a small amount of air (carryover) is leaked between the air streams. Airflow carryover is not a concern for most occupancies; however, energy wheels should not be used for spaces with potentially contaminated airflow (labs, sensitive medical facilities, kitchen hoods, painting areas, etc.).

- Frost protection is required for energy wheels in cold climates

- Energy wheels located in cold climates are subject to frosting when the cold outdoor air strikes the moisture aden wheel. There are several strategies to alleviate this issue (electric pre-heat coil, bypass damper, wheel modulation); however, these solutions reduce the energy efficiency of the system somewhat. Frost protection strategies do not preclude the use of the wheel; however, they should be taken into consideration when determining if an ERV is appropriate for the particular installation.

Final Thoughts

Energy Recovery Ventilators have a lot of advantages that can save money over the long run, and provide a better quality environment for the occupants of the building. Whether your facility is new construction or an existing building, ERV’s can offer savings and convenience throughout the life of your HVAC system. ERV system design requires an expert mechanical engineer who has the necessary training and experience to ensure they are properly applied. If your next project warrants the use of an energy recovery method, please contact Schnackel Engineers for assistance.

Comments

Comments are closed.